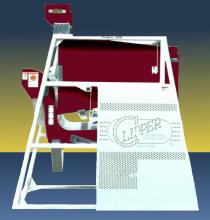

The Clipper Eclipse 334 is a cleaner designed to meet the low maintenance and easy cleanout requirements of today's seedsman. The Eclipse 334 is built with the same care and craftsmanship as Clipper's larger precision cleaners.The Clipper Eclipse 334 features a heavy-duty tubular steel frame, 13-ply marine grade plywood shoes, scotch ply hangers and a heavy-duty eccentric counter balanced shoe drive. The Eclipse 334 shoe has been designed with three 34 x 34" screens: One screen for the top and the other two for lower separation. Over 150 different sizes of perforated metal or wire cloth screens are available. Commodity Flow: The commodity is fed into the hopper and is spread evenly across the full width of the top screen. The product then moves across the top screen, which has openings larger than the product itself. The large foreign material is "scalped" off while the good product falls through the screen. The bottom two screens are set up for split flow sifting. The bottom screen openings must be smaller than the commodity being cleaned. Trash, weed seeds and splits drop through the bottom screens while the good product passes over them. The bottom two screens can also be set up as a scalp/sift flow by removing the two-way splitter. Next, the product is routed through a column of air from the bottom blast fan. This blast of air effectively removes any lightweight trash and dust that may have remained after screening.Good clean product is discharged at the bottom of the air chamber.

Standard Features:

Heavy-duty tubular steel frame

Counter balanced throw for smooth operation

Heavy duty 1-1/2" eccentric drive shaft and drive

Shoe made from high performance 13-ply marine grade hardwood plywood.

Scoth-ply shoe hangers

Easy connection to an auger or vibratory conveyor

Capacities:

Soybeans, Wheat, Corn - *250 BPH (fast clean), *120 BPH (precision clean)

Rice, Oats - *190 BPH (fast clean), *75 BPH (precision clean)

*Note: capacities may vary depending on seed condition, moisture content, seed varieties, types, and volumes of contaminants to be separated and the percentage of foreign material acceptable in the final product. Capacities also vary depending on product flow through the cleaner. Capacities shown above are for the split flow arrangement.

Options:

Over 175 different sizes of perforated metal or wire mesh material to accommodate virtually all agricultural commodities.

Single phase, 50 hertz, Ex-Proof drives are available

Electronic variable speed bottom fan

Surge hopper with site glass

Poly auger option with 2 way bagger and 1/3Hp drive

24" stand available to elevate cleaner if needed.